Revolutionizing MMW Systems: The Crucial Role of Cryogenic Isolators

Millimeter wave engineers operate in a part of the electromagnetic spectrum where there are some significant challenges to overcome. It is difficult to generate signal power, the available components are costly and sometimes don’t work well, and often the components just don’t exist at these frequencies. In fields such as radio astronomy, designers must go to great lengths to reduce the noise floor to improve detection sensitivity. Cooling their MMW systems to cryogenic temperatures to minimize noise is a common practice.

A system is built and tested at room temperature and works well. But when cooled, it has less than stellar performance. What is the problem? Cooling should improve the system performance. But some components, including Faraday rotation isolators designed for room temperature operation, do not work well at cryogenic temperatures. Why would this be the case?

Temperature’s Impact on Isolation Performance

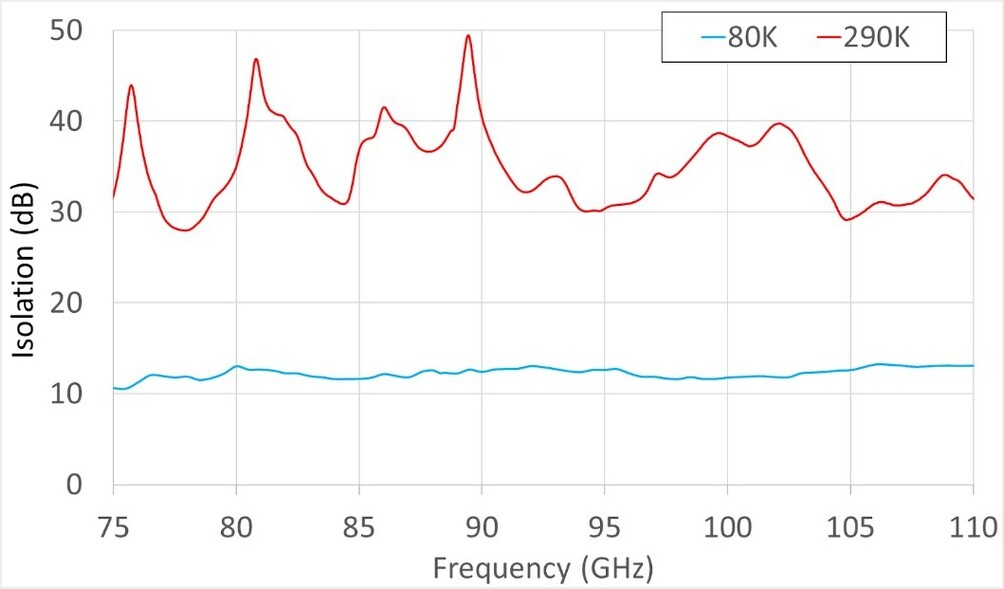

Well to start with, the ferrite rod, which affects the performance of a Faraday rotator, has properties that are temperature dependent. A good room temperature isolator that gives 30 dB of isolation can degrade to 12 dB isolation when cooled to 80K. That’s a huge change!

Magnetic Bias Field Dynamics in Cryogenic Environments

A second potential contributor to changes in performance relates to the magnetic bias field. A ferrite must be biased with an external magnetic field. The strength of a magnetic field produced by a permanent magnet is also affected by lowering the temperature. Standard Faraday rotation isolators are precisely tuned by varying the magnitude of the bias field to achieve the best isolation at room temperature. But once the temperature decreases, both the Faraday rotation rate and the magnetic field will change. There is no guarantee that the isolator will perform well.

Engineering for Cryogenic Success: Stress Mitigation and Robust Design

Finally, any component that is made of constituent parts precisely held together will undergo significant stress points when cooled. Micro Harmonics performed extensive cycling of our cryogenic isolators in liquid nitrogen and made design adjustments to mitigate these stresses. How frustrating it would be to use a room temperature isolator in a cryogenic system and have it fail due to loss of integrity in the assembly.

Our cryogenic isolators have been specifically designed for operation at cryogenic temperatures. The ferrite rods are designed to ensure the required 45° rotation of the signal when cooled. The neodymium bias magnets are replaced with samarium cobalt magnets which maintain their strength at cryogenic temperatures. Materials for support structures are selected to minimize mechanical stresses arising from cryogenic cycling. Our cryogenic isolators are routinely RF tested at 25 K in our cryostat using a vector network analyzer and frequency extension modules. The isolators have been tested down to 1K and shown to have very good RF performance. If you would like to read a detailed article on this topic, click here!

Founded with a commitment to pushing the boundaries of millimeter wave technology, Micro Harmonics specializes in engineering solutions for the most challenging electromagnetic spectrum segments. Our dedication to innovation extends beyond cryogenic isolators, encompassing the production of cutting-edge circulators and attenuators. Explore the forefront of technology with Micro Harmonics – where precision meets excellence. If you have any additional questions, please contact us!