Micro Harmonics offers a complete line of Faraday rotation isolators covering 25-400 GHz in every standard waveguide band from WR-28 through WR‑2.8. These isolators exhibit state-of-the-art performance in terms of low-insertion loss, broad-bandwidth, low port reflections, and the highest frequency coverage in the industry. They are the most advanced isolators on the market today.

“The compact size, extremely low insertion loss, and the wide bandwidth have allowed us to use isolators in a wider variety of our systems than was previously possible and have led to significant improvements in key system performance metrics such as source power and sensitivity.”

Jeffrey Hesler, Ph.D.

CTO, Virginia Diodes

“They had an isolator with the single most important parameter I needed, low insertion loss. They were ultimately able to select one with just 1.2 dB loss at 240 GHz, which is pretty phenomenal.”

Curt Dunnam, Director of Operations

ACERT National Biomedical Center at Cornell

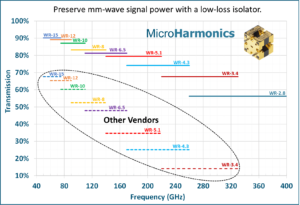

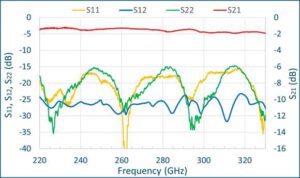

The graph below shows the insertion loss of our isolators as compared to other vendors. The insertion loss of our WR-3.4 isolator is only 2 dB. Don’t waste valuable mm-wave signal power by using an isolator with high insertion loss. Join the many companies who are using our isolators in their systems and seeing tangible improvements in system performance.

| Model | Flange (EIA) |

Band (GHz) |

Insertion Loss (dB, typ) |

Isolation (dB, typ) |

Max Power (W)* |

|---|---|---|---|---|---|

| FR280 | WR-28 | 26 – 40 | 0.5 | 23 | 5.0 |

| FR188 | WR-19 | 40 – 60 | 0.5 | 20 | 4.3 |

| FR148 | WR-15 | 50 – 75 | 0.6 | 23 | 3.8 |

| FR122 | WR-12 | 60 – 90 | 0.5 | 20 | 3.5 |

| FR100 | WR-10 | 75 – 110 | 0.6 | 25 | 2.9 |

| FR090 | WR-9 | 82 – 122 | 0.9 | 21 | 2.7 |

| FR080 | WR-8 | 90 – 140 | 0.8 | 24 | 2.4 |

| FR065 | WR-6.5 | 110 – 170 | 0.8 | 25 | 1.9 |

| FR051 | WR-5.1 | 140 – 220 | 1.1 | 22 | 1.3 |

| FR043 | WR-4.3 | 170 – 260 | 1.3 | 22 | 1.0 |

| FR034 | WR-3.4 | 220 – 330 | 1.8 | 23 | 0.6 |

| FR028 | WR-2.8 | 260 – 400 | 2.7 | 21 | 0.4 |

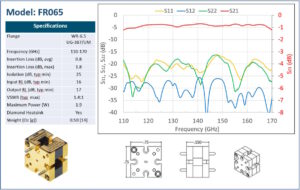

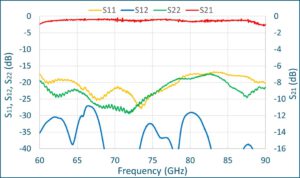

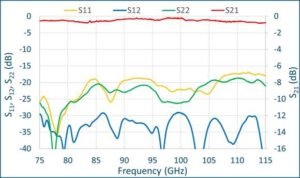

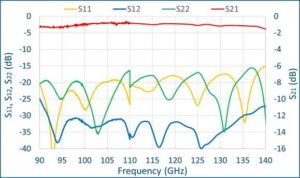

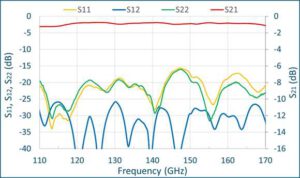

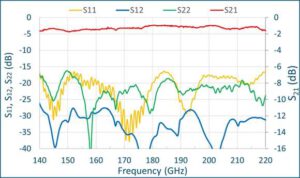

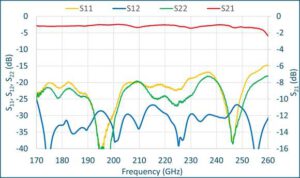

A typical specification sheet is shown below. Every component is thoroughly RF tested and the data for each individual component is shared with the customer. Our isolators employ a unique diamond heatsink for improved power handling and reliability. Our isolators are resistant to stray magnetic fields. We use anti-cocking waveguide flanges. All our products are fully guaranteed. We design and manufacture all our products in the United States.

Faraday Rotation Isolators – Sample Test Data

FR122: 60-90 GHz |

FR100: 75-110 GHz |

FR80: 90-140 GHz |

FR65: 110-170 GHz |

FR51: 140-220 GHz |

FR43: 170-260 GHz |

FR34: 220-330 GHz |

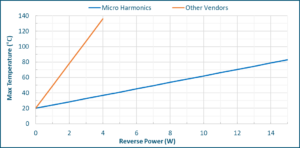

|

Isolator Power Ratings – In a Faraday rotation isolator, reverse power is absorbed in a resistive layer and converted to heat energy. In the legacy isolators sold by other vendors, the resistive layer can get hot because it is thermally isolated. But Micro Harmonics isolators employ a diamond disc that provides an excellent path to conduct heat from the resistive layer to the metal block. Data from our thermal simulations of WR-10 isolators are shown in the graph below. Simulations indicate a max temperature of 50°C in the legacy isolators at the rated power level of 1 W. A Micro Harmonics WR-10 isolator reaches 50°C when absorbing 7 W. See “Diamond Heatsink Technology” section for more info.

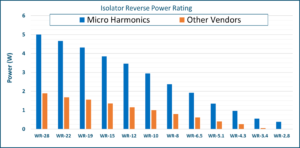

The graph below shows the maximum reverse power ratings of our isolators and the average of other vendors. The MHC power ratings are conservative to ensure low temperatures and long life.

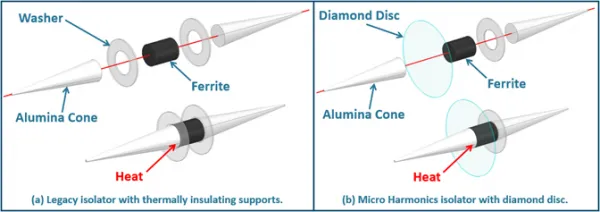

Diamond Heatsink Technology – Our isolators employ a unique diamond support disc that allows them to handle greater reverse power levels and operate at lower temperatures. At the heart of a Faraday rotation isolator are a pair of alumina cones and a ferrite rod. The cones are used to couple signals from the waveguides to the ferrite. The cones are bisected by a resistive layer along their central axis. In most commercial Faraday rotation isolators, the ferrite and cones are suspended by a pair of washer-shaped supports as shown in the left-side sketch below. The support material is typically BOPET, Styrene, a resin, or some other material with a low dielectric constant and low loss at mm-wave frequencies. These materials are generally in the class of thermal insulators and thus the cones and ferrite are thermally isolated from the metal block.

Signals entering the output port of the isolator pass through the ferrite rod and are absorbed in the resistive layer bisecting the input side alumina cone. The absorbed power is converted to heat energy. Very little of this heat energy can be channeled away by thermal conduction through the washer-shaped supports, rather it must be dissipated through a radiative process or by means of convection through the surrounding air. The resistive layers are thus subject to high heat levels and even damage if too much reverse power is incident on the device. Historically this was not an issue as there was very little power available at these frequencies. But as higher power sources are becoming available there is a renewed interest in the power ratings of these devices.

At Micro Harmonics we have replaced the input support washer with a uniform high-grade optical CVD diamond disc. The diamond disc does not have a hole at the center. Diamond is the ultimate thermal conductor approaching 2200 W/m·K, more than five times higher than copper. The diamond disc is sandwiched between the base of the input cone and the ferrite rod and is in intimate contact over the entire area of the cone base. This is the optimal location for the diamond disc since it is the region subject to the highest heat levels. The diamond disc is attached to the metal waveguide block over its periphery and provides an excellent conduit to channel heat away from the resistive layer. The thermal conduction path is clearly superior and thus our isolators operate at much lower temperatures.

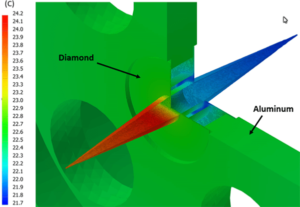

The graphic to the left shows the result of a thermal simulation of our WR-10 isolator. The resistive layer in the left side cone is treated as a heat source equivalent to the power absorbed from a 1 W RF signal. The maximum temperature is 24°C in the left side cone. No thermal gradient appears across the diamond disc. The high thermal conductivity of the diamond disc effectively ties the cone base to the aluminum block temperature. A 7 W RF source gives a max temperature of 50°C in our WR-10 model.

Thermal simulations indicate a maximum reverse power rating of 7 W for our WR-10 isolators. But we have taken a conservative approach and set the maximum reverse power rating at 2.9 W. When a Micro Harmonics WR-10 isolator absorbs a 2.9 W signal travelling in the reverse direction, the maximum temperature should not exceed 10°C above the ambient waveguide block temperature. In contrast, the simulations indicate a max temperature of 80°C above ambient for a legacy isolator absorbing 2.9 W.

This link will take you to our power rating webpage where we provide a more in-depth look at our thermal models and how we use them to establish power ratings for our isolators.

Micro Harmonics Isolators are Insensitive to Stray Magnetic Fields – Have you seen the label on the legacy isolator that warns you to keep it away from magnetic fields? You will not find that label on a Micro Harmonics isolator because our isolators are highly resistant to external magnetic fields. The legacy isolators use a highly tuned magnetic field that is easily perturbed by even a small external magnetic field. This causes under- or over-rotation of the signal and severe performance degradation. Micro Harmonics isolators use a highly saturated magnetic bias field which makes them insensitive to stray magnetic fields. The phenomenon is explained in more detail in an article published in the April 2021 edition of the Microwave Journal.